– by Lavi Pal Singh, AVP – Retail with AstorMueller shoes &

Amit Chopra, Managing Director, Shoes & Accessories

“Like a butterfly stuck in a chrysalis, waiting for the perfect moment, I was waiting for the day I could burst forth and fly way and find my home.” Emme Rollins, Dear Rockstar

COVID has given an advantage to re-look, re-work on our strength and to strategize our priorities to capitalize on up-coming opportunities in the footwear sector both local and global. The footwear world is complex and seasonal with product lines consuming a wide abundance of raw materials and components with high dependencies on world supply chain and mainly china for materials.

Vocal for Local

With Atmanirbhar campaign gaining strength, recent claims of #VocalforLocal by many industry experts, need a basic self-check if we stand true to claims:

Production or merchandise offered under brand name and in retail are all manufactured locally including components.

Advantage India

- 2nd largest producer of footwear

- 95% of production being consumed locally

- Highest livestock & bovine population

- Abundant manpower

- World’s youngest workforce

Adoption of social compliance norms by manufacturers and suppliers to ensure, it helps in upliftment of work force and in fact doing justice to nation.

India has high competency levels being intelligent and uses skills whenever any opportunity arrives to adopt “Jugaad concept”and find for unique cost-effective solutions, thus redefining the new normal.Government has made claims in these difficult times about easy land availability and capital support for development of Infrastructure, to support its atmanirbhar mission. Migrant issue has further highlighted the huge labor availability and their venerability, offering opportunity to restructure the systems.

In these times, it is need to re-look at our competencies and gaps for in-build in-efficiencies like low production flexibility, productivity and resistance to change in the ever-changing world requirements, which may help us understand what is hindering our global position for growth.

Something Seems a Miss

Government support on factors like export incentives, subsidy, tax rebates, low cost of capital and change in labor laws may provide temporary reliefs but do they suffice for industry objective global dominance in medium to long term? Hike in import duties may help at domestic level but may not suffice to support on global competitiveness and may bring higher in-efficiencies besides increase in production costs.

We need to understand China wasn’t built in a day. How we catch up fast needs to be the focus and what efforts our industry needs to be put needs be put into consideration.While India exports have been on de-growth near neighbors i.e. Vietnam, Indonesia, Pakistan, Bangladesh have been showing growth trends. Such times we need to educate ourselves about best practices of China and Vietnam for production, automation, infrastructure and efficient work culture to work on a better and highly professional system for value addition.

Way Forward – It’s time to Reboot

The Industry needs to have a re-look, re-think from a new Perspective for our inherent strengths and plug the gaps to present a comprehensive framework to improve our global competitiveness and stand high in world.

Points to Ponder

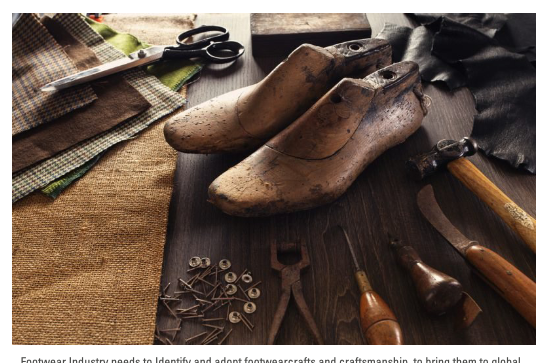

Revisiting and setting an efficient and highly productive manufacturing eco-system:

Development of self-sustained – small footwear industry townships with in-build Govt. social objective for society upliftment can be a new thought. Industry presently offers footwear cluster model across Chennai, Agra, Kanpur and other towns or cities, which though help but at same time competes within itself and requiring much more resources.

A mini footwear township model with multiple shoe factories build on economies of scale along with MSME units for components and ancillary units. Each manufacturing unit, providing specific manufacturing and product core competency across footwear categories and shoe constructions like men’s leather formals or sneakers or non-leather- Formal or Casuals; Goodyear welted; Blake; stuck-on; Vulcanized etc. Thus, all units complementing and supporting each other in peak and low season periods instead of competing among players. Each unit working on its economies of scale, offering highest quality and best competitive prices at global level which need to be difficult to match. An Ideal manufacturing scenario with win-win for both manufacturer and buyers.

We need to go back into the pages of history over decades when visionary entrepreneurs like Tata, Bata and others set up manufacturing systems with such ideas of self-sustainability, meeting social upliftment motive. Good practices need to be picked, evolved and adapted with new objective of – a multi-company, mini-township concept. States like UP, Bihar and West Bengal, with huge migrant labour density, offer to be best key potential zones.

Mechanization/automation

Productivity comes from automation and adoption of advanced machinery and production systems. Low labor costs though important but for higher competitiveness there is critical need to improve on productivity through rapid automation.

We need to engage local machines manufacturers, to make advanced machines for footwear sector at nominal costs to upgrade to state-of-the-art infrastructure. China provides a huge example, how they localized most of machinery over last few decades to develop their advanced infrastructure.India doesn’t lack on engineering excellence but same has not been exploited as we have been dependent on import of machinery.

Industry needs to tie up engineering and management institutes like ITIs, IITs, IIMs and others for incubation of ideas for development of innovative machines, manufacturing systems and solutions, which can help rapid scaling up; mechanization and improve productivity thus providing higher efficiency and lower costs. Productivity is one of major key where India needs to really work on.

Enhancing Economies of Scale:

“Our footwear export units has always struggled on production scaling. There are only a few, who have capability to manufacture over 5000 per day from a single production unit (i.e. 1.5 million prs a year). Thus, companies put up multiple production units acrosscity, town with low production volumes from each.This need to be given a real thought when, we think of replacing China and Vietnam as a production hub.We need to understand our weakness, as to why our production system flounders, when the production levels go higher, thus need for multiple production units, stretching our resources, management and infrastructure to manage business besides impacting profitability.

Strengthening raw material supply chain

Raw Material and component have been India’s major weakness for decades now. There is urgent need to rebuild entire value chain. Presently it is highly import dependent for most of raw materials mainly non-leather (synthetics; meshes; foams), and even for small things like trims, embellishments, finishing creams, molds etc. For leather and outsole, it does have a bit of self-reliance.

The manufacturing industry needs to engage with component manufacturers in a more positive way atindustry level. They need to assure the component industry of support though keeping three critical key objectives for competency i.e. Quality, delivery and price aligned.

We also need to understand that China,which in last few years has worked on its “Plus one Strategy”. They built their eco-system keeping the material development, raw materials, and knowledge intensive value part within their country and moving manufacturing to neighboring countries like Vietnam, Bangladesh and others. They invested in countries with lower manufacturing costs and thus reaping advantage fromtheir Free Trade agreements or lower custom duties. India thus needs to catch up majorly by working on setting up highly efficient component base.

Bridging Skill Gaps

The dynamic world and our stagnant education systems.The Industry specificSkill development institutes like FDDI; CLRI; CFTA: need to undertake major overhaul of methodology and curriculum for the training imparted to evolve new skill sets for the next Gen. From the present objective of job seeking graduates and limiting knowledge to books, they need to drive for broader visions targeted and focused towards new ideas for R&D; material innovations; innovative product designing and production systems with global vision. These centers need to be incubation points driving entrepreneurial skills for startups with global advanced practices, product designing with their original fashion ideas, more from commercial aspects, thus helping support existing brands, companies for global recognition or establish their own brand labels. We need to take a leaf from the efforts of institutes like NIFT;supported by Fashion Design Council of India (FDCI) whose alumni’s like Rohit Bal, Manish Arora, JJ Valaya, Sabyasachi Mukherjee and many others, made India to be recognized as a global fashion hub with its niche and uniqueness.

Promoting and marketing our USP and strengths for global competency

Sustainability:

The new global keyword mantra is Sustainability and responsible fashion.Leather has for centuries has been our strength, is bio-degradable natural material and a by-product of meat industry.Footwear industry needs to change the narrative, and market leather from sustainable material context. Synthetic footwear being mainly plastics (PU and PVC), and many marketing them with false narrative as vegan leather for its cost advantage. It leaves a worse environmental impact, taking over 1000 years for degradation. We need to sell the idea of leather being a by-product from meat consumption and leather industry helping utilizing food industry waste, which if left un-used, may have worse environmental impact. The biggest misconception about leather being linked with animal cruelty; need to be clarified more aggressively and communicated through proper narratives.

India needs to utilize and promote aggressively its competitive advantage for leather build over years. India was one of first and few countries in Asia to define and implement environment laws and better practices for tanning with Chemical Effluent plants set up since early 90’s to leave minimum environment impact. Compared to China, Vietnam, Bangladesh and others in Asia, India has the maximum no. of audited and rated tanneries by Leather Working group (133 no. of which 87 are Gold rated) for its high production systems, which is an achievement.

We need to work on a “Leather mark” concept, adopting idea from the government initiative during1990’s of an “Eco mark” label for quality. The idea needs to be re-brushed with new definitions for material specifications; guidelines; practices for material traceability and production processes. Certified “Leather mark” products, to be our mark of strength on quality and sustainability, which can be marketed globally, giving us a competitive edge. The case what “Woolmark” impact had for woolen Industry.

At same time the leather experts, need to keep working, and innovating for new and better practices to offer even better sustainable product thus assuring reduction of carbon footprint and environment impact. This involves research, innovation for better processes and practices related to leather tanning which require less use of synthetic chemicals and water; Leather tracing from end to end; and re-cycling of factory wastes and water.The whole system needs to be defined and marketed to offer what world looking for.

Exploiting India’s ethnic strength

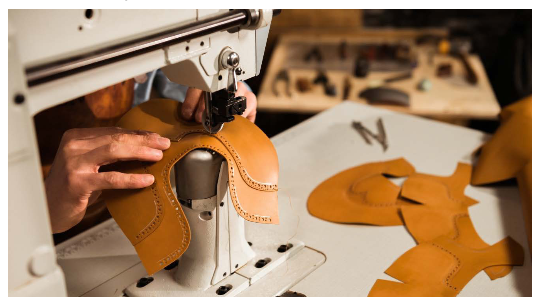

There is huge unexploited footwear market potential of original craftsmanship for ethnic footwear to be brought in forefront for products like Kohlapuri’s, Jutti’s, Mojarii’s; Paabu boots, pula chappals besides many others. The Indian apparel fashion designers under FDCI, brought many such hidden craftsmanship practices to global recognitions for apparels benefiting all partners – brands, craftsman and bring recognition to our country Indian fashion trends.

Footwear Industry needs to Identify and adopt footwear crafts and craftsmanship, to bring them to global level recognition at much higher scale. There is a need to train craftsmen by adoption of better production practices; develop products suiting present times, engageat bigger commercial level, and support them with a bigger defined objective. Fashion partners like FDCI need to be aligned for footwear industry, to present and promote footwear crafts during global fashion events to create a unique global identity for these products, keeping heritage and craftsmanship uniqueness alive.A good example is the marketing of Khadi which have been adopted by brands over last few years.

Presently these have been adopted but are at very limited small scale, and in most cases benefit not accrued to craftsman. It neither helps their upliftment, their skills or Industry in totality and most time concepts used with original craft being compromised and name misused to offer a completely different product, thus losing on its heritage value to commercialization and higher profit objective.

India is a highly entrepreneurial country and Industry needs to be ready to exploit for all available opportunities to create scope for growth and profits. Industry needs to re-work to scale up with a fresh blueprint;reset its priorities and present a comprehensive strategy to government to showcase what Industry can offer. A self-reliant India needs be interpreted as producing high quality goods for Indian and global consumption with a high value addition and at same time being highly productive and competitive in value in global market. It should help social upliftment providing employment and additionally providing a decent livelihood to its workforce.