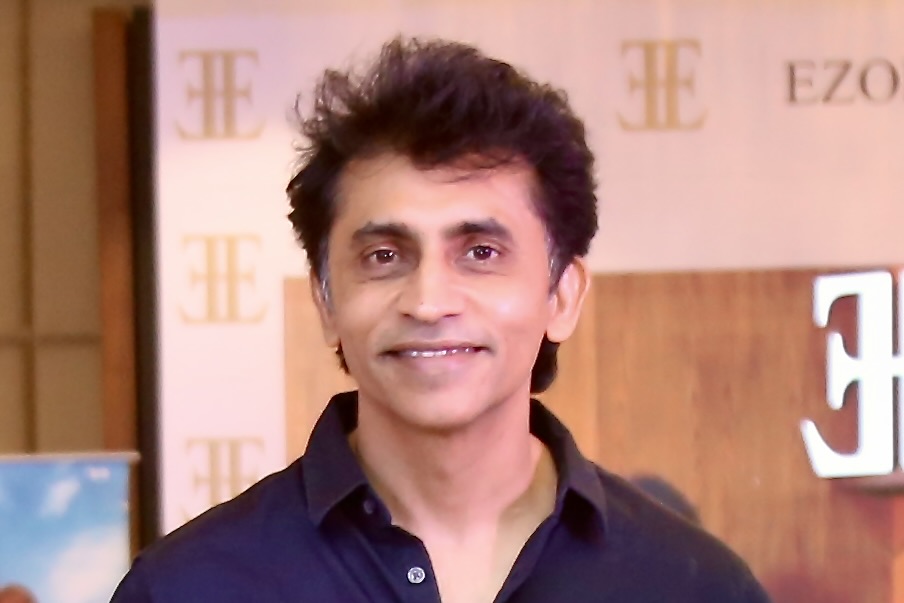

Blog By Arvind Bajaj, Ezok Shoes, footwear enthusiast and connoisseur

In the bustling world of fashion, where trends come and go like whispers in the wind, one aspect remains constant—the meticulous craftsmanship that goes into creating every pair of shoes. Behind the shimmering storefronts and glossy advertisements lies a world of creativity, precision, and dedication. Join me as we embark on a journey behind the scenes of shoe manufacturing, unravelling the intricate process from design conception to final assembly, while shedding light on sustainable practices and ethical considerations in the industry. The design team at Ezok, renowned for their avant-garde approach to footwear, embraces this ethos wholeheartedly.

Design Conception: Where Creativity Takes Root

At the heart of every pair of shoes is a spark of inspiration, a concept waiting to be brought to life. The design conception phase is where creativity thrives, as designers sketch, prototype, and refine their ideas. It’s a collaborative process that often involves trend analysis, market research, and a deep understanding of consumer preferences. Designers draw inspiration from diverse sources, be it nature, art, architecture, or cultural heritage. They experiment with shapes, materials, and colours to create visually striking and functional designs that resonate with the target audience.

Material Selection: The Building Blocks of Quality

Once the design is finalized, attention turns to selecting the right materials. From luxurious leathers to high-performance synthetics, the choice of materials plays a crucial role in determining the comfort, durability, and aesthetic appeal of the final product. For Ezok, quality and sustainability go hand in hand. In recent years, there has been a growing emphasis on sustainability and ethical sourcing in the shoe industry. Manufacturers are increasingly opting for eco-friendly materials, such as recycled plastics, organic cotton, and responsibly sourced leather. By prioritizing sustainability, brands not only reduce their environmental footprint but also contribute to the well-being of workers and communities involved in the supply chain.

Prototyping and Testing: Perfecting the Fit and Function

With materials in hand, the design moves from concept to reality through prototyping and testing. Skilled craftsmen and technologists bring the design to life, meticulously cutting, stitching, and molding each component of the shoe. Prototypes undergo rigorous testing to ensure they meet quality standards for comfort, fit, and performance. This iterative process involves feedback from wear testers, experts and quality assurance teams. By fine-tuning the design based on real-world feedback, manufacturers strive to create shoes that not only look good but also feel great to wear.

Manufacturing: Where Precision Meets Scale

Once the prototype is approved, it’s time to scale up production. Modern shoe manufacturing facilities are marvels of efficiency and precision, combining automation with skilled craftsmanship to produce shoes on a large scale without compromising quality. Assembly lines buzz with activity as workers expertly assemble each shoe, following detailed instructions and quality control measures. Cutting-edge technologies, such as 3D printing and robotic stitching, streamline production processes while ensuring consistency and accuracy.

Sustainable Practices: Paving the Way for a Greener Future

In recent years, the shoe industry has faced scrutiny over its environmental impact, from carbon emissions to waste generation. In response, many brands are embracing sustainable practices to reduce their ecological footprint and promote environmental stewardship. One key area of focus is waste reduction. Manufacturers are exploring innovative ways to minimize waste throughout the production process, whether it’s through efficient material usage, recycling initiatives, or circular design principles that extend the lifespan of shoes.

Moreover, sustainable sourcing practices are gaining traction, with brands prioritizing suppliers that adhere to ethical labour standards and environmental regulations. By fostering transparency and accountability in their supply chains, brands can build trust with consumers and contribute to positive social and environmental outcomes.

Ethical Considerations: Upholding Worker Rights and Well-being

As we journey behind the scenes of shoe manufacturing, the story of Ezok serves as a shining example of excellence, innovation, and responsibility. Beyond environmental sustainability, ethical considerations also extend to labour practices within the shoe industry. Historically, the industry has faced criticism for labour exploitation, including low wages, long hours, and unsafe working conditions in factories. To address these concerns, many brands are taking proactive steps to ensure fair labour practices throughout their supply chains. This includes partnering with certified factories that uphold labour standards set forth by organizations. At Ezok we follow REACH standards.

Arvind Bajaj, the mind behind EZOK Shoes, began in humble surroundings, but his vision soared globally. His parent company, Amar Shoes, thrives with cutting-edge facilities in Agra and Noida, employing over 1200 and leading the industry.