ROMANS CAD Software provides the solution by integrating not only the traditional 3D/2D CAD tools but with material database and smooth integration to the shop floor. It has been successfully implemented in various projects linking design team and manufacturing team. In a conversation with S&A, Jean Marc Pedeboy, Partner at Stratégies: Romans Cad Software said, we are moving from island of productivity, to collaborative design and manufacturing.

As the Indian footwear industry eyes for more precision in product designs, how Roman Cad can play a bigger role?

Consumers are changing the development process, some brands are now moving to 4 collections per year putting lots of pressure on retailer’s designers’ and factories. E-commerce has jumped on the opportunities, forcing retailers and brands to strike back, through an extensive digitalization of their processes. These new consumer’s experiences will force the industry to have a holistic view on the design process, which will work not only for Indian exporters but also for local retailers.

ROMANS CAD Software provides the solution by integrating not only the traditional 3D/2D CAD tools but with material database and smooth integration to the shop floor. ROMANS CAD have been successfully implemented in various projects linking design team and manufacturing team regardless of their location, providing a solution to those challenges.

Tell us how wide is the application of a technology like Romans Cad in other countries in comparison with India.

At ROMANS CAD, in the last 10 years, we have been working closely with major brands to implement successfully all these concepts:

A major US client with more than 15 brands has connected 3D Design, material database, Pre- Costing in the US and manufacturing in China and Vietnam, making the supply chain of information seamless.

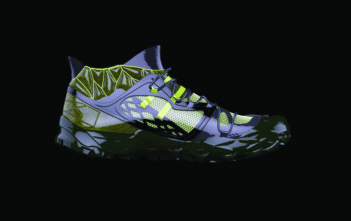

Another sport brand is going one step further by connecting the factory shop floor to the collaborative processes through Internet Of Things. Retailers are now using 3D digital images on social network to detect trends, without any physical samples.

Who in India have successfully started using your technology? Kindly discuss some of the drastic changes it has brought.

In India mainly we have been successful with local brands such as VKC and Condor.

Where in India do you see new clients?

Retailers like in the US and Europe should be the leader of this design to manufacture revolution. Some big US retailers are now moving to India so the market is really global.

You have been a keen observer of the Indian footwear industry. What are some of the challenges does the industry face and what measures would like to see?

I don’t thing Indian footwear industry have realized the changes due to the digitalization, and how it will impact theirs business. We are moving from island of productivity, to collaborative design and manufacturing.

I’ve heard owner of big footwear companies telling me until the brands ask them they will not do anything. Since others countries are moving fast, the attitude should change to adopt more proactive attitude, factories have to scale up in providing more services to the brands, and retailers.

At the last FDRA conference in Washington majors brands were quite clear they are looking for companies who are able to provide full digital design service.

Since they can 3D print realistic samples for their show room, they can answer more efficiently to consumer’s demands.

Like in US, Indian companies should hire a director of innovation reporting directly to the CEO.

The industry should also:

- Create a material database in a standard format in order to help companies in their digitalization process. For example, all tanneries components vendors should be able to provide free of charge their product in a digital format.

- Attract designers from others industry and schools which are familiar with 3D tools.

What’s your growth projection?

We faced the same problem in China 5 years ago with the implication of retailers have changed the game and now all these countries are moving fast. India has IT and footwear skills but has not yet seen the great opportunity. Assuming footwear companies address all these issues India has everything to become THE FOOTWEAR DESIGN HUB OF THE WORLD.